Project Overview

Yichang Humanwell Pharmaceutical Co., LTD is the largest R&D and production enterprise of narcotic drugs in Asia. This project covers an area of about 66 acres. The total designed cooling capacity of the cooling system room is 51MW, which can ensure the intelligent and intelligent energy supply of the air conditioning system and process glycol system of the whole workshop.

- Plan and advantages

-

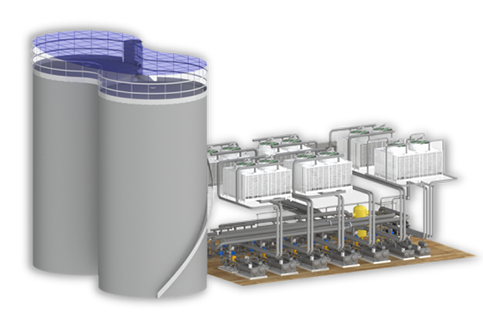

For the Yichang Humanwell Headquarters base project, OaseTECH designed and built an efficient cold storage energy center with 51MW cooling capacity, providing efficient cooling systems for each production workshop and comfortable air conditioning systems for the office R & D building.

OaseTECH has built 22,000 cubic meters of cold storage tanks according to the price difference between peak and valley electricity in the local area. It takes full advantage of the low electricity price at night for efficient cold storage and uses them during the high electricity price in the daytime, which can save more than 30% of the electricity cost for customers every year.

The high efficiency BIM design and factory prefabrication module provided by OaseTECH achieved the energy efficiency of Yichang Humanwell Plant Energy Center system > 5.0, and won the "Blue Sky Cup" High Efficiency Energy Center award.

According to the demand of each production workshop and office R & D building of this project, OaseTECH built 51MW high efficiency cold storage energy center, which adopted the comprehensive energy supply scheme of base-load refrigerator + dual-operating refrigerator + cold storage tank combined cooling + intelligent operation.

The overall planning of the energy center adopts the design concept of modular integrated efficient room. Through BIM modeling in the deepening design stage of the room, the energy transmission system, heat exchange system and energy efficiency optimization system in the room are all modeled 1:1 by the modular integration scheme. The conveying module and the chiller are arranged one to one to reduce pipe resistance and loss of cold capacity. At the same time, the pipe is centrally laid as far as possible to effectively save room space. By optimizing and rationalizing the layout of the system, the overall water resistance of the transmission pipe network in the machine room can be reduced, which lays a good foundation for energy saving and consumption reduction after the completion of the system.

The conveying module adopts factory prefabrication and assembler construction after arriving at the site, saving 50% of the site processing operation area and 80% of the site construction time. By optimizing the layout of modules and pipelines, the floor occupation of the energy center machine room is reduced. The machine room has a visiting channel, which improves the demonstration and display function of the project.

The chilled water transmission and distribution system adopts the two-stage pump system. Through the coupling of the hydraulic balance device, the transmission and distribution system is divided into two water loops: the production side of the cold source and the user side of the load. The first stage pump only bears the resistance of the system in the cold source side station, and the head of primary stage pump is greatly reduced, which reduces the initial installed capacity and equipment power. The second stage pump bears the resistance of the outer loop of the station, and is supplied according to the demand of different terminal. Compared with the direct supply type transmission and distribution system, the comprehensive power consumption of circulating pump is reduced by about 30%.

Compared with the conventional control system, 20% monitoring control points are added in this project to realize the one-button start-stop and timing switch of the refrigeration room system (including the terminal hydraulic balance control system). Fully automated unattended intelligent energy operation management and cloud data remote service (data storage, statistical analysis, remote optimization) functions such as hierarchical automatic alarm, remote monitoring, active safety warning are realized. All equipment is automatically adjusted according to load. Party A's operation management personnel need not participate in the system's energy-saving operation management, but are only responsible for on-duty and safety emergency support.

At the same time, according to the price difference between peak and valley electricity, two 11000m³ cold storage tanks were built to make full use of the low electricity price at night for efficient cold storage, which can be used during the high electricity price in the day. The strategy of parallel operation of two tanks can ensure that the main engine under two working conditions is in the high efficiency operation range and maximize the utilization of the valley power period, which can save more than 30% of the electricity cost for users every year.