Project Overview

As the final assembly and manufacturing center of COMAC, Commercial Aircraft Corporation of China (COMAC) undertakes the final assembly and manufacturing tasks of regional aircraft and trunk aircraft, take the important mission of China's civil aircraft development, and ranks among the world's first-class final assembly and manufacturing enterprises in the field of civil aircraft. Among them, the ARJ21 is the first new medium-short range turbofan regional aircraft of 70-110 seat class, which is developed and produced in accordance with international airworthiness standards and has independent intellectual property rights. It is mainly used to meet the requirements of radial routes from central city to surrounding small and medium-sized cities. Located in the middle of Pudong base production area of Shanghai Aircraft Manufacturing Co., LTD., No. 919 Shangfei Road, Pudong New Area, Shanghai, the ARJ New regional aircraft assembly plant with a construction area of 23,000 square meters can provide assembly site for multiple ARJ21 aircraft at the same time.

- Plan and advantages

-

OaseTECH provides efficient heating system for ARJ21 new regional aircraft batch production department. Its service scope covers aircraft final assembly, department assembly, office buildings and other production rooms, which provides important support for the mass production of ARJ21 aircraft, and does a good job in ensuring the manufacturing and production of ARJ21 and other aircraft, so as to promote the domestic regional aircraft to a broader stage.

The air conditioning system in the production and loading department of ARJ21 new regional aircraft is divided into the air conditioning system of the main workshop and the air conditioning system of the annex building, and the terminal adopts the winter and summer co-management. According to the technical requirements, a comfort layered air conditioning system was designed in the main workshop hall, and OaseTECH provided a centralized heat exchange system for winter heating in the air conditioning system. The heat source of the air conditioning system is 60~50℃ hot water, which is manufactured by the efficient plate heat exchange unit through heat exchanging from the high temperature hot water(130~70℃).

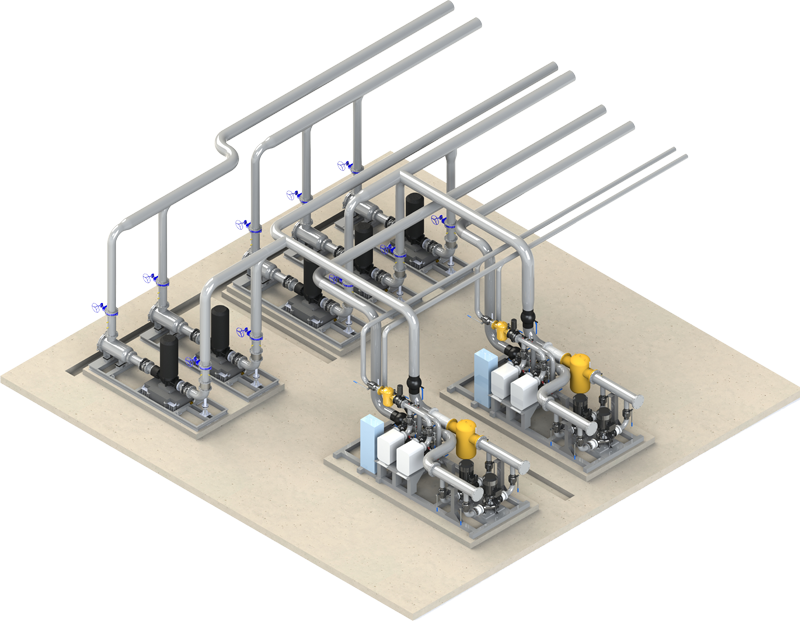

According to the distribution of air conditioning load, OaseTECH optimized the design of heat exchange system in air conditioning station. The heat exchange system adopts two sets of integral skid mounted design scheme, each set of system double plate and double pump efficient heat exchange unit, pressure maintaining system, soft water system. on-site installation only requires connecting the system with the interface and outface of the unit. High efficiency heat exchange unit adopts high efficiency brazing heat exchanger, small size and high heat exchange efficiency. The AI intelligent control system of OaseTECH ensures stable and reliable water supply temperature, with temperature fluctuation controlled within 0.5℃. In daily use, the two systems operate independently, and one of them has the function of mutual backup in case of failure, which can help users save energy costs and guarantee the comfort and safety of the heating system.